TBM 260 / READIMOIST

TBM 260 and ReadiMoist™ measures moisture directly in a bin and rapidly provides moisture data to the batching control system to allow real time adjustments to the process.

TBM 260 is used for any kind of material while ReadiMoist™ is specific to the concrete industry.

TBM 260 and ReadiMoist™ description

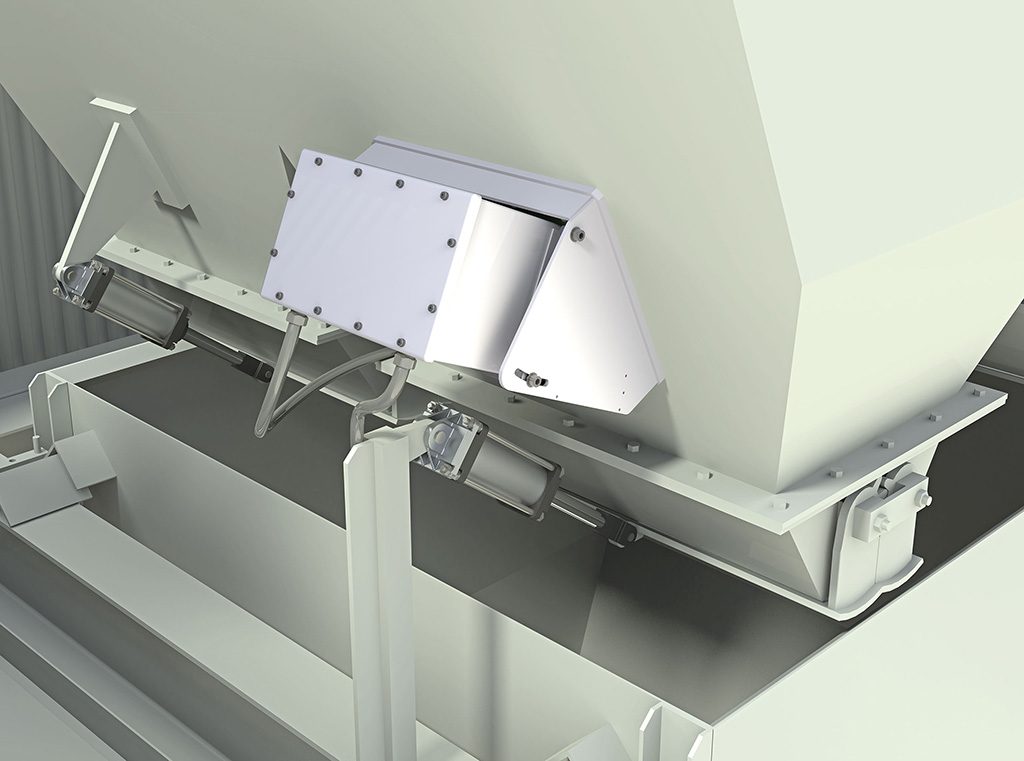

TBM 260 and ReadiMoist™ comprises of microwave antennae and an electronics cabinet. The antennae are attached to either side of the bin near the clamshell gates. A low frequency microwave beam is transmitted through ~1 metre of falling material in the bin. Digital measurement of microwave group delay and attenuation allows precise moisture analysis every second.

Microwave windows and antenna brackets are supplied for easy installation on the bin, that mount flush with the inside hopper surface and prevent material build up and do not interfere with material flow. The microwave beam interrogates a large volume of material (typically about 60 litres) which greatly reduces errors caused by moisture heterogeneity.

An industrial PC calculates results, saves data and interfaces to the plant. A wide range of plant interface options are available using industry standard interface modules.

A ‘gate open’ signal from the plant triggers moisture analysis while the material drops to ensure synchronisation with batch process activities.

TBM 260 and ReadiMoist™ advantages

- Accurate moisture analysis of large volume

- Removes the need for routine sample collection

- Allows automatic batch control

- Does not penetrate into bin or obstruct material flow

- Flexible plant interface options

- Patented state-of-the-art digital microwave technology

- Industrially proven

- Extremely reliable and low maintenance

- PC-based with remote access for prompt support

ReadiMoist™ installs on sand bins at concrete batching plants to accurately measure moisture content as the sand drops into the mix. This allows precise control of the moisture content in the final concrete mix to ensure the correct strength and slump specification.

Accurate sand moisture measurement can improve the consistency and quality of your concrete, the efficiency of your batching process, and provide significant cost savings on cement.

"increasing automation will produce more information for improving mine operation"

Marcus Adams, PSI Mines and Roads, Mining Weekly, October 2015