NATURAL GAMMA SERIES

NATURAL GAMMA analysers use the natural gamma radiation (K, U, Th) signature of the material and known correlations with the composition to derive ore quality information.

A feature of many ores and associated rocks like coal is that they usually contain trace amounts of potassium, thorium and uranium. Within any individual deposit, the absolute amount of these elements usually varies in direct proportion to the amount of different constituents of the ore. By using a very sensitive high performance detector, combined with careful shielding of to exclude other natural radiation such as solar and terrestrial radiation, the Natural Gamma Monitor can determine the concentration of the target elements or ash content with a suitable precision for many quality management applications.

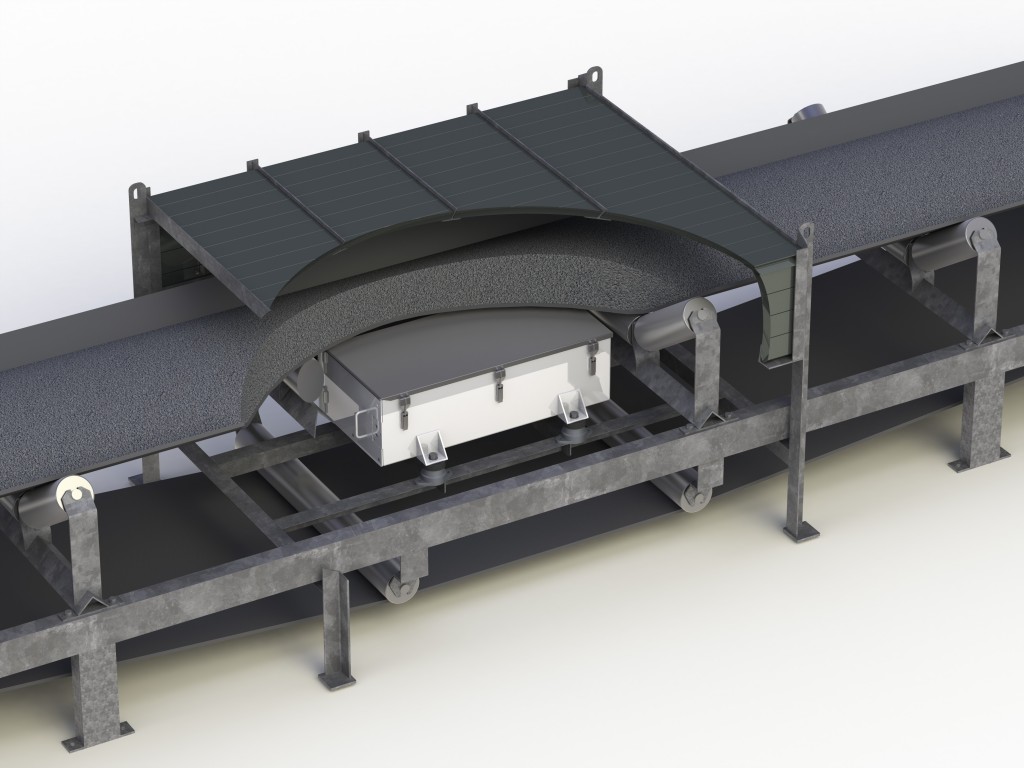

They are economical on-line ore quality monitoring systems which are easily installed directly under production conveyor belts. The systems don’t contain any nucleonic source and therefore don’t require site to obtain a radiation license for their use.

The major features of the Natural Gamma Series include:

- Easy installation and simple operation

- No radiation sources – no requirement for licensing

- Under belt configuration – suitable for coarse ore and high tonnage applications

- Fully automatic operation – no operator intervention required

- No moving parts – low maintenance costs

- Automatic electronic stability checks – drift free performance

- Calibrations customised to each material – maximising measurement precision

- Real time, reliable data produced to meet application needs

- No operational upper limit to particle size or conveyed bed depth

- Flexible system interface to suit specific site requirements

- Non-contact technique – no high wear components

- Superior total cost of ownership

- Designed for long product lifecycle

Related Products

"It is vitally important to realize that an accurate knowledge of the grade of the ore that is mined, processed, and railed to the port is crucial to quality control and blending operations"

Dr Ralph Holmes Sampling and Analysis Conference 2013