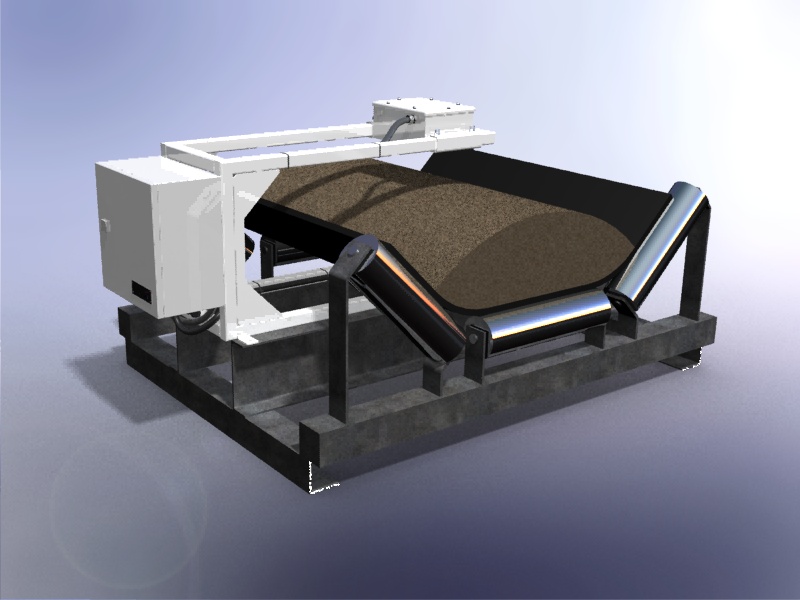

ReadiMoist TBM 210 / TBM 220

Scantech’s ReadiMoist TBM Series microwave moisture analysers use proven technology successfully implemented in hundreds of installations in many commodities over decades, continuously refined and improved through successive generations of advancements in hardware and software.

Microwaves are transmitted through the process material to the receiver. The technology is not affected by segregation, as the microwaves pass through all the material and measurements are independent of material size and flow rate.

TBM 210 is the standalone option and TBM 220 is the model used when integrated with other analysers and therefore does not require its own enclosure.

Advantages of the TBM 210 / 220 high frequency microwave systems including:

- Continuous, full material thickness analysis,

- Proven, reliable and short customised calibration process,

- Higher frequencies provide superior performance (over low frequency systems) in certain materials under certain conditions, e.g. shallower beds, less attenuating materials,

- Compensates for varying flow rates,

- Robust frame mounts to conveyor structure, clamp-on frame option avoids drilling,

- No contact with the conveyor belt or process material,

- Stainless steel frame and enclosure options, remote cabinet option.

Case study: A major global gold producer increased ore throughput by 3% ($75M/year extra Au content) by increasing feed rate using measured moisture from a TBM 210 from the month after it was installed and calibrated, instead of relying on previous assumed moisture “factor”. An evaluation process against other vendors clearly demonstrated the advantages of Scantech’s calibration process. A “leading” competitor’s local “reference site” showed their moisture analyser has not been able to be successfully calibrated 5+ years after installation.

"A continuous, online analysis is far superior to regular samples taken by a sampling tower and subsequently tested in the laboratory"

Dr Michael Clark ICR March 2012