COALSCAN SERIES

Historically COALSCAN has been Scantech’s flagship product range.

The first analyser sold by Scantech was the COALSCAN 4500 in the early 1980s. Since then, the bestselling analyser has been the COALSCAN 3500, of which more than 150 have been installed all over the world.

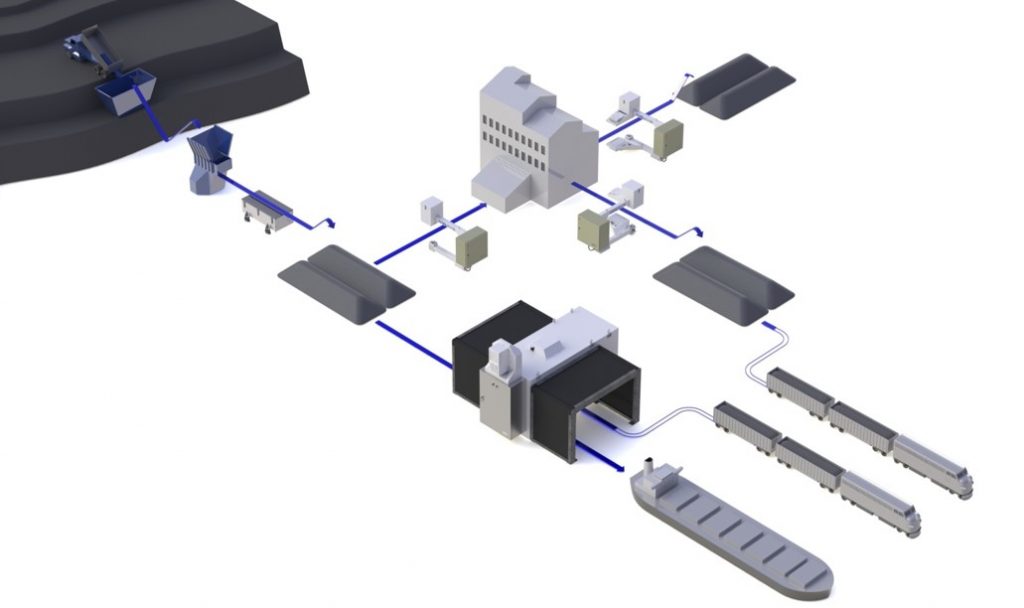

The COALSCAN range of analysers has now evolved into the widest range of online coal analysers offered by any company.

Hundreds of plants around the world are using COALSCAN analysers to increase yield and make their operators’ working lives simpler and more productive.

As well as building on Scantech’s worldwide reputation for outstanding reliability, you will find the latest generation of COALSCAN is also amongst the easiest to operate and afford. Operators benefit from Scantech’s 40 years’ experience designing, installing and maintaining on belt coal analysers.

Billions of tonnes of coal have been processed more efficiently because of COALSCAN analysers, optimising the use of resources. COALSCANs are also used to optimise coal blending and coke quality utilised in steel manufacturing.

Related Products

"Real-time analysis combines the capabilities of online analysers, mechanical sampling systems, and advanced computer technology to allow buyers, sellers or traders to monitor and correct loading or blending, while these activties are in progress"

Evans et al, SGS, World Coal August 2014