BLENDSCAN SERIES

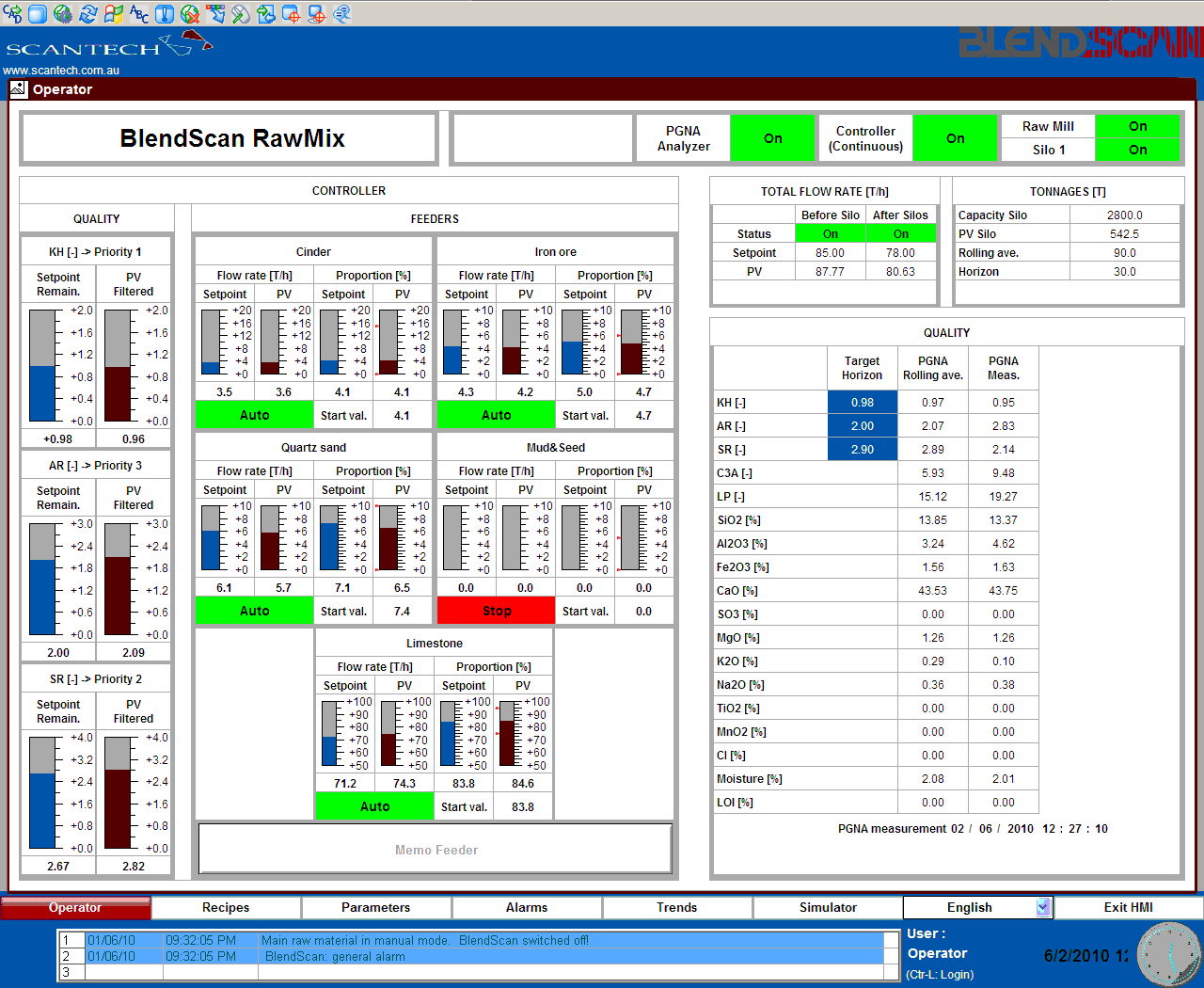

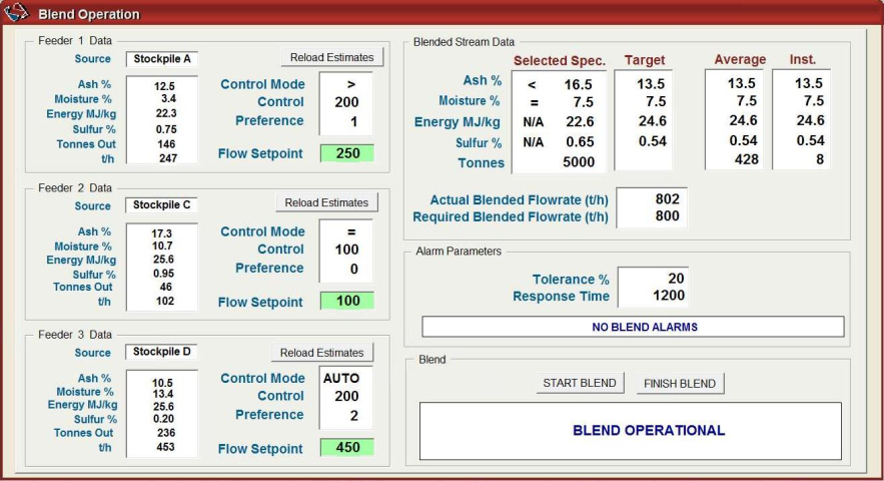

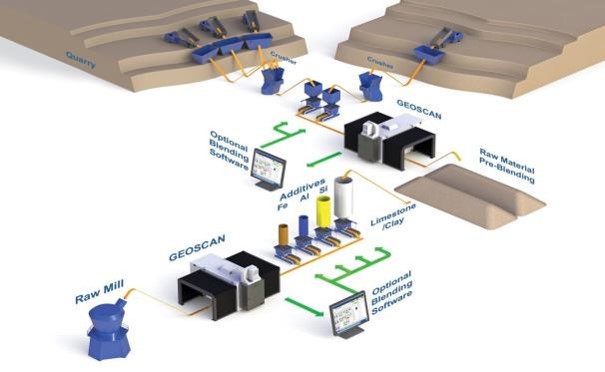

BLENDSCAN softwares are used to automate and optimise quality control of conveyed materials.

In conjunction with our GEOSCAN-C, COALSCAN 9500X and BALZSCAN 9500X analysers, these process control packages will help control and minimise material quality variation sent to stockpiles, placed onto transport, or fed into processes.

More consistent feed to processes can improve performance by 10% or more. This can include fuel savings, equipment wear, water and reagent consumption, and additive costs in addition to process performance to generate more consistent product quality and yields.

Related Products

"Accurate online measurement information and diagnostics show how the plant is working; a single piece of data can make or break the process"

Paul Moore International Mining 2013