Power Generation

Fossil and Alternative Fuels (AF) burning / Optimised combustion

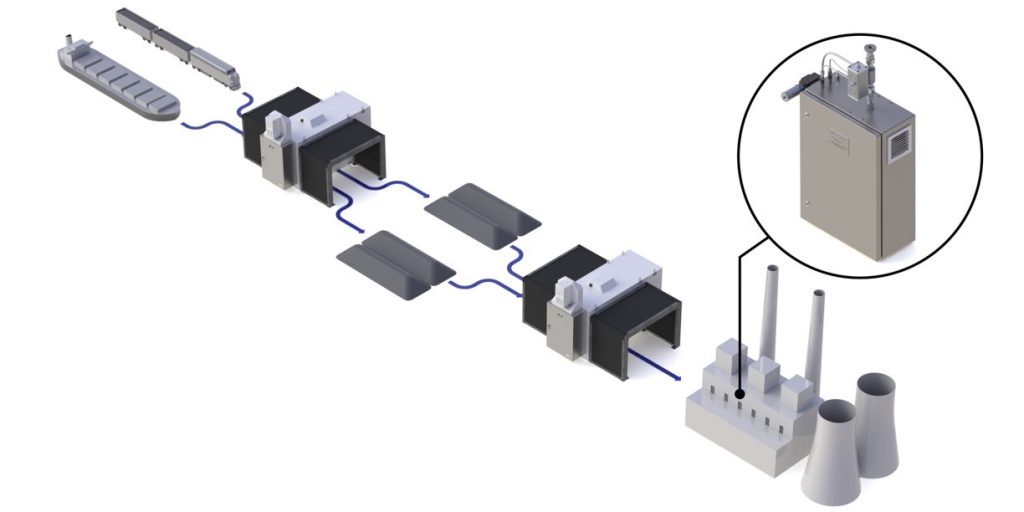

Power Stations receive fossil or alternative fuels from various sources and implement measurement systems to:

- Ensure fuels specifications are respected,

- Sort fuels to build stockpiles according to Ash content, Chlorine and Sulphur content, Calorific Value

- Blend fuels according to characteristics to minimise variations and run boilers smoothly…

Many Power Stations sell fly ashes to the construction and cement industries. It is imperative to have an accurate and reliable knowledge of their Carbon content.

There are few proven technologies that can measure conveyed flows to produce representative, continuous analysis over useful time increments for effective quality and process management. We can assist in the following applications:

- Fuels quality control – elemental analysis

- BALZSCAN 9500X – Alternative Fuel mass elemental analyser (including Chlorine) based on PGNAA Technology

- COALSCAN 9500X – Fossil Fuel mass elemental analyser based on PGNAA Technology

- BLENDSCAN COAL – software for blending or sorting coal from / to several yards

- Fuels quality control – Ash content and Calorific Value (CV) monitoring

- BALZSCAN 2100 – Alternative Fuel ash content and CV analyser based on DUET Technology

- COALSCAN 2100 – Fossil Fuel ash content and CV analyser based on DUET Technology

- Fuels process and quality control – Moisture Monitoring

- ReadiMoist TBM 210 – Through Belt Moisture microwave monitors

- Fly ash quality control – Unburnt Carbon monitoring in fly ash

- CIFA 350 – In air duct Carbon content monitor for optimised combustion control

Scantech works closely with clients to discuss the customisation of data measurement frequency, analyser specification and appropriate precisions to suit process control requirements to ensure maximum benefit of measurement data and its smooth integration into plant operations.

"Real-time analysis combines the capabilities of online analysers, mechanical sampling systems, and advanced computer technology to allow buyers, sellers or traders to monitor and correct loading or blending, while these activties are in progress"

Evans et al, SGS, World Coal August 2014