Cement & Concrete

Production of Cement and Concrete

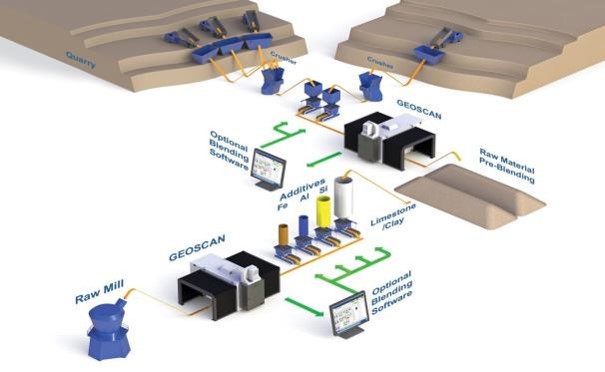

Scantech provides the cement and concrete sectors with online analysers for a wide range of applications and locations. Over the past three decades, Scantech analysers have become a standard process control tool in the Cement Industry.

We provide real time quality analysis of Raw Materials for Premix, additives for Raw Mix, Fuels or Concrete ingredients. Our software can minimise Stockpile and Raw Mix variability by controlling feeders. We are active in the following applications and sectors:

- Stockpile building and Raw Mix process and quality control – Material elemental analysis and feeder control

o GEOSCAN-C – Mass elemental analyser based on PGNAA Technology

o BLENDSCAN CEMENT – Software for blending materials before stockpile or before raw mill

- Fuels quality control – Elemental analysis

o BALZSCAN 9500X – Alternative Fuels mass elemental analyser based on PGNAA Technology

- Fuels quality control – Ash content and Calorific Value (CV) monitoring

o BALZSCAN 2100 – Alternative Fuel ash and CV analyser based on DUET Technology

- Raw Materials, additives, fossil and alternative fuels quality control – Moisture Monitoring with ReadiMoist TBM 200 series

o TBM 210 / TBM 230 – Through Belt Moisture microwave monitors

o TBM 260 – Through Bin Moisture microwave monitor

o TBM 280 – Through Bale Moisture microwave monitor

- Concrete components dosing – Moisture Monitoring

o TBM 260 ReadiMoist – Through Bin Moisture microwave monitor

Scantech works closely with clients to discuss the customisation of data measurement frequency, analyser specification and appropriate precisions to suit process control requirements to ensure maximum benefit of measurement data and its smooth integration into plant operations.

"Operators who seek out the latest technologies to increase efficiency and improve their product will not only see a better bottom line, but will also achieve greater social recognition"

Gordon Cope, World Coal, December 2014