Coal

Coal mining and beneficiation

Raw brown or black coal quality is variable according to the seam nature and location and this has a big impact on the washing efficiency. Knowing washed coal quality allows coal suppliers to use it for metallurgical or thermal customers.

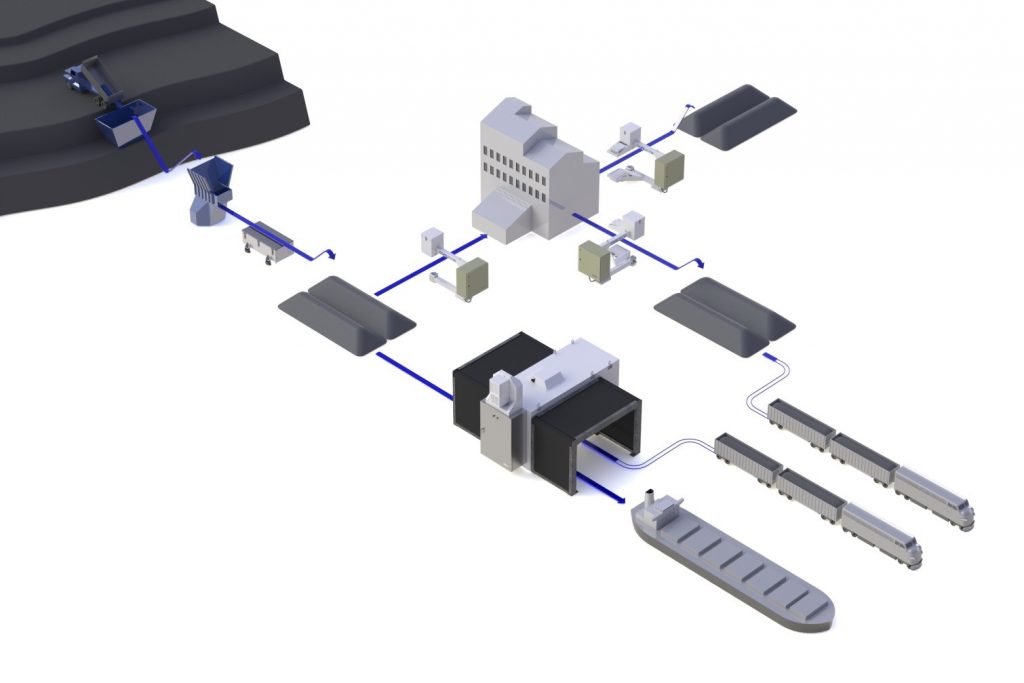

There are few proven technologies that can measure conveyed flows to produce representative, continuous analysis over useful time increments for effective quality and process management. We can assist you in the following applications:

- Raw or washed coal quality control – elemental analysis

- COALSCAN 9500X – Coal mass elemental analyser based on PGNAA Technology

- BLENDSCAN COAL – software for blending or sorting coal from / to several yards

- Raw or washed coal process and quality control – Ash content and Calorific Value (CV) monitoring

- COALSCAN 2100 – Coal ash content and CV analyser based on DUET Technology

- COALSCAN 1500 – Coal ash content analyser based on Natural Gamma Technology

- Raw or washed coal process and quality control – moisture monitoring

- ReadiMoist TBM 210 – Through Belt Moisture microwave monitors

- Raw or washed coal process control – Particle size monitoring

- SizeScan – 3D Particle size distribution, oversize and volume monitor

Scantech works closely with clients to discuss the customisation of data measurement frequency, analyser specification and appropriate precisions to suit process control requirements to ensure maximum benefit of measurement data and its smooth integration into plant operations.

"A continuous, online analysis is far superior to regular samples taken by a sampling tower and subsequently tested in the laboratory"

Dr Michael Clark ICR March 2012