BLENDSCAN COAL

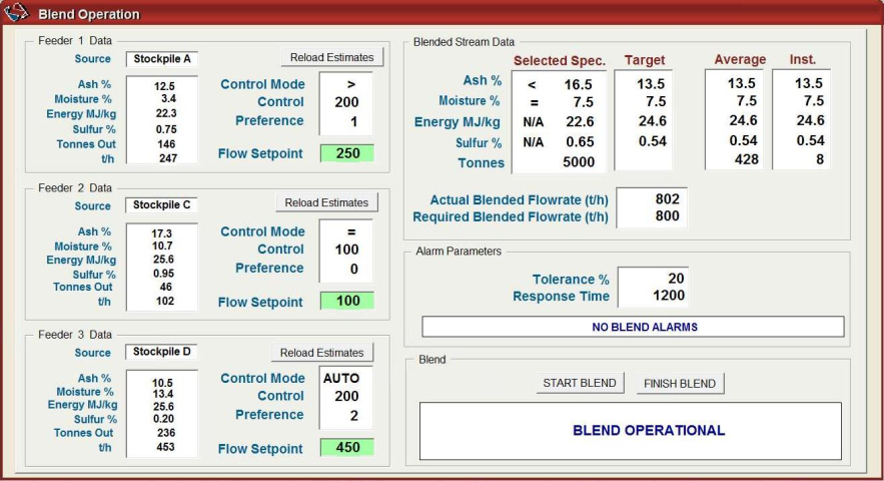

BLENDSCAN COAL software for coal blending control is provided to ensure that the quality of the coal sent to the yard, load out, bunkers and boilers is consistent and within specifications.

The software takes data from real time analysers to improve real time control for ash, Chlorine, and Sulphur content to ensure optimal energy production for boilers by controlling quality and minimising risk of exceeding environmental limits in power generation, or meeting composition specification in metallurgical coal.

"Significant value added is evident as a result of the installation of process control analysers"

Moodley and Minnett SAIMM 2009