Moisture Control in Concrete Batching

Concrete plants worldwide face the same results when trying to monitor moisture on the aggregates: regardless of the method (e.g. sample once every shift, once every batch or use probes), they always need to add extra cement to compensate for the unknown moisture content and be certain that the concrete meets the specifications on contract.

In a single aggregate pile, hand-samples are totally inacurate as the moisture will vary enormously, and therefore the representativeness of a scoop is low.

Using invasive probes, also been demonstrated to have limited representivity. Further, the probes accumulate material on and around them, which in time reduces their representivity even more.

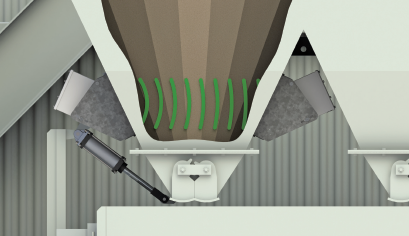

Considering the price of cement is one of the largest expenses in concrete batching, Scantech was asked by a client to look at the problem and develop a solution. The ReadiMoistTM uses microwave technology capable of reading up to 60 litres of material at any given second and, because the antennae lay flat on the bin walls, it does not accumulate material nor requires expensive parts exchange due to wear off as the electronic components are never in contact with the materials inside the bin.

Please refer to the ReadiMoistTM page or click to enquire about this product.

""The economic benefit gained from use of the Coalscan on-line ash monitors in most cases results from control of mining and plant operations closer to the required specification ash content. A number of independent studies have estimated the benefits of on-line ash analysis to average more than A$500 000 per year per installed gauge.""

csiropedia.csiro.au March 2011