BLENDSCAN CEMENT

BLENDSCAN software options for cement plant blending control are provided to maximize the benefits of real time measurement and active control to achieve the best performance from your plant.

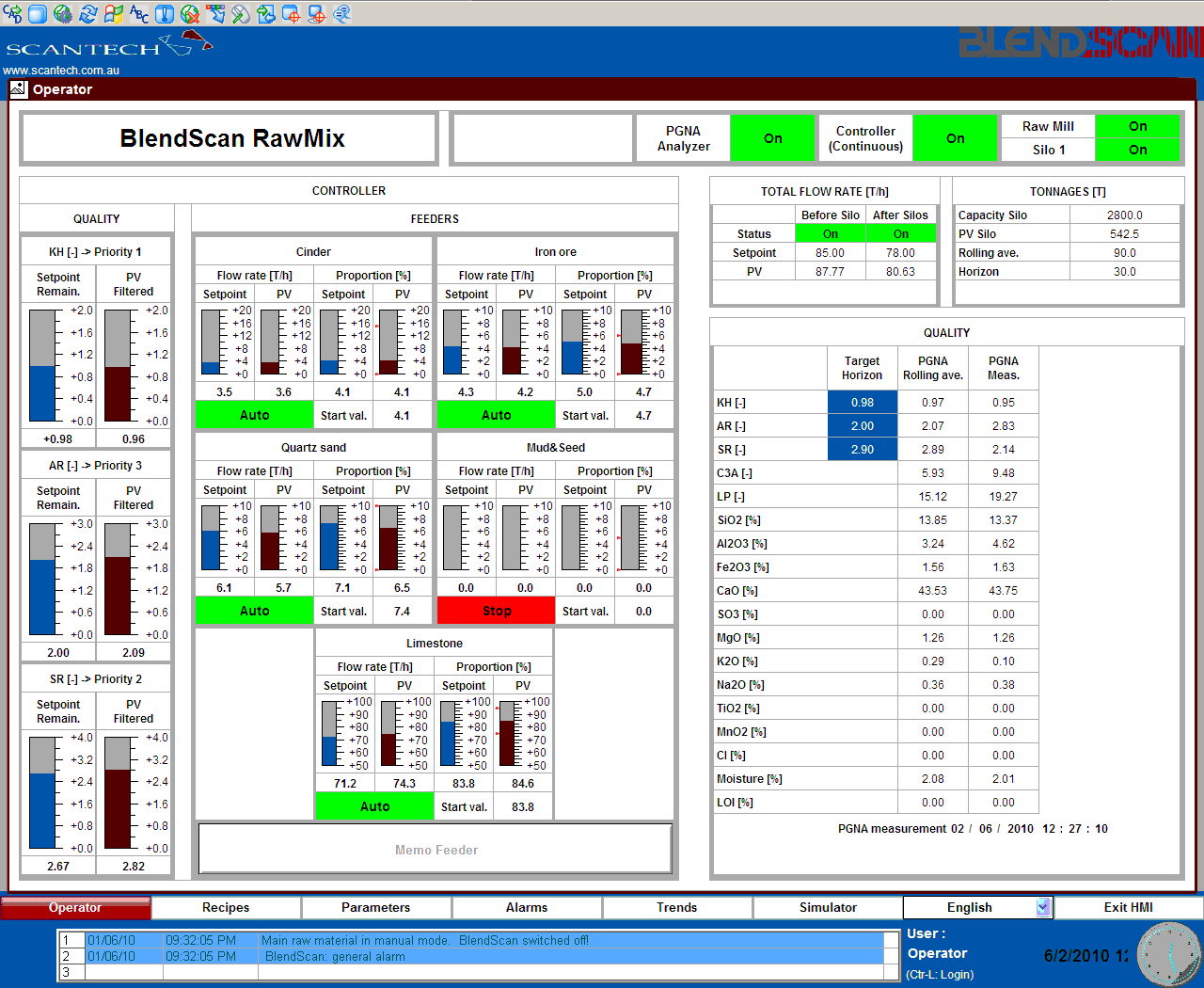

The software is used to automate and optimise quality control of conveyed materials. In the cement industry, BLENDSCAN PILE OFFLINE and BLENDSCAN PILE ONLINE optimise limestone or marl pre-blending while BLENDSCAN MILL optimises raw mix blending.

In conjunction with our GEOSCAN-C PGNAA analyser, this software will help you minimise any variation in the material quality being sent to the stockpile, kiln or mixing silo;

- BLENDSCAN PILE ONLINE / OFFLINE will help reduce LSF standard deviation at an early stage in the process, building a more consistent stockpile and therefore improving the pre-homogenisation. This can significantly reduce the additive requirements in raw meal.

- BLENDSCAN MILL will help reduce LSF standard deviation before the raw mill. It will automatically optimise the quantity of additive required for achieving a given material quality. Combined with BLENDSCAN PILE control it becomes a fine-tuning process rather than the workhorse for achieving desired raw meal composition.

"Accurate online measurement information and diagnostics show how the plant is working; a single piece of data can make or break the process"

Paul Moore International Mining 2013