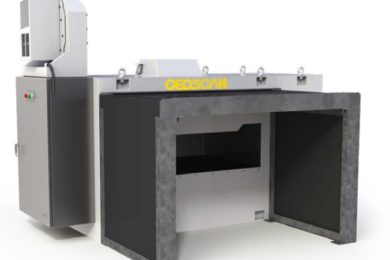

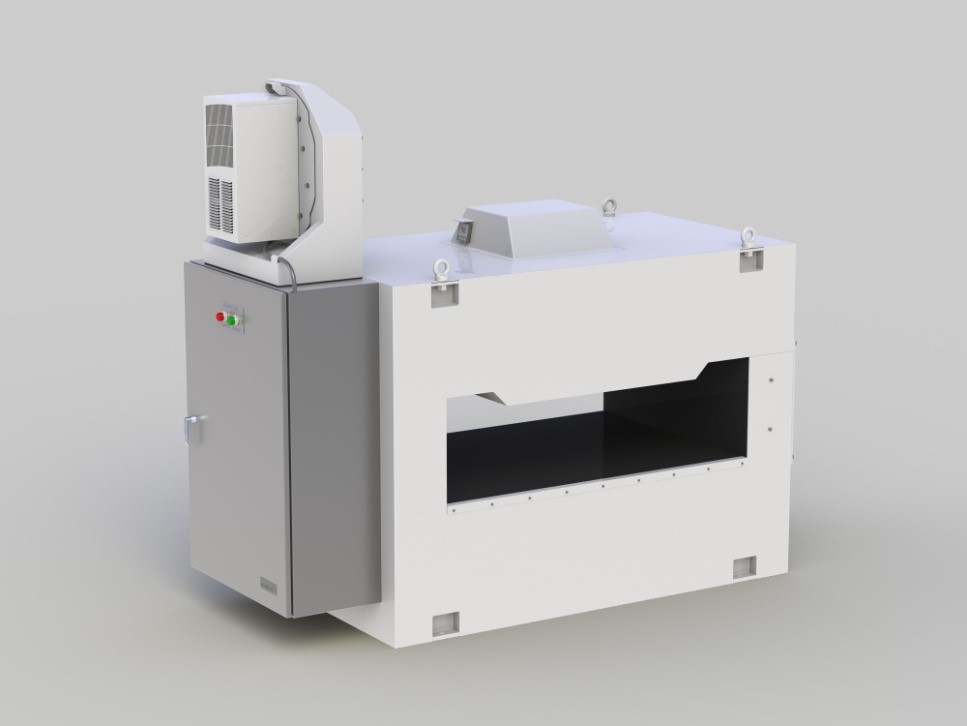

GEOSCAN SERIES

The GEOSCAN is an On-Belt Elemental analysis system for monitoring bulk raw materials such as limestone and iron ore as well as material blends, concentrates, sinter, scrap, etc.

It can be used on a very wide variety of applications, with automatic bed depth correction included as a standard feature. It has a patented non-contact design and requires minimal maintenance.

The GEOSCAN continuously analyses conveyed materials in real time, providing accurate results every 2 minutes as standard, or as often as every 30 seconds for demanding process control applications. Since the GEOSCAN fits on existing conveyor belts, additional sampling equipment, transfer points and material handling equipment are not required.

The GEOSCAN utilises the technique known as Prompt Gamma Neutron Activation Analysis (PGNAA). The GEOSCAN incorporates high efficiency detectors and state-of-the-art digital spectrometer, which overcomes the limitations of conventional, low efficiency detection systems. The optional moisture analyser uses the microwave transmission technique to measure the moisture content of the material.

Equipment configurations and output data frequency and precisions (through our Rocks2data module) are customised to suit each application to optimise benefits.

Related Products

"Operators who seek out the latest technologies to increase efficiency and improve their product will not only see a better bottom line, but will also achieve greater social recognition"

Gordon Cope, World Coal, December 2014